CNC Plasma Cutting

Plasma Cutting done to perfection.

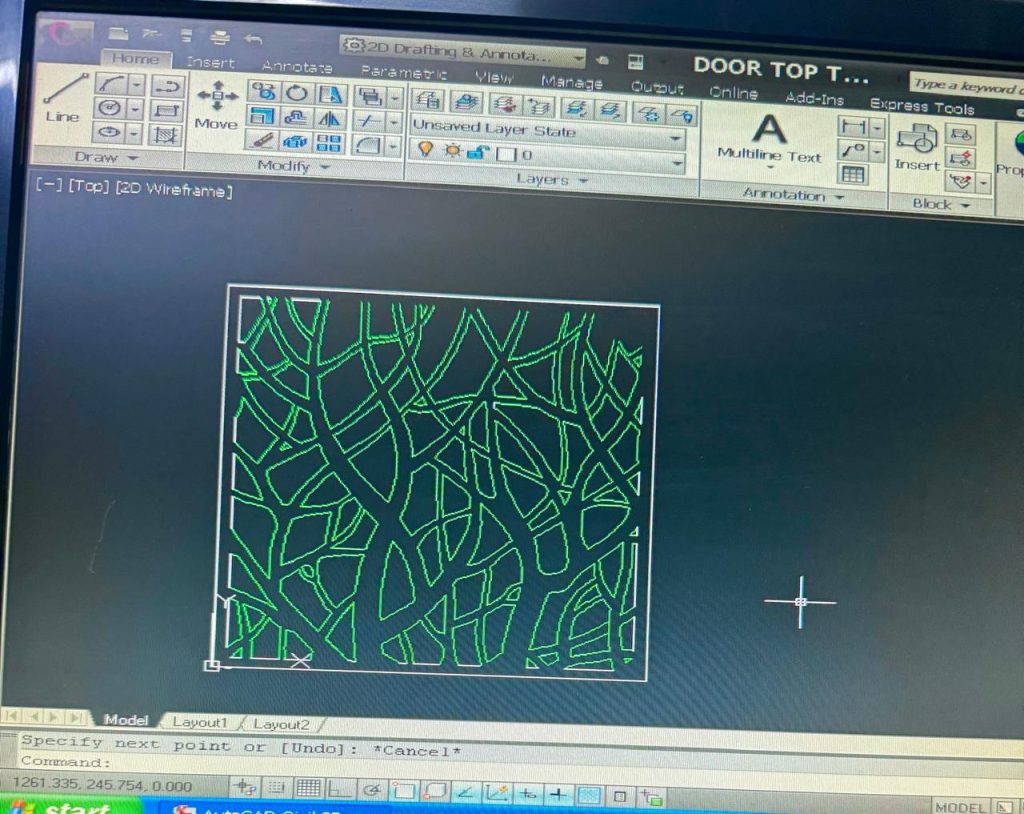

🔨 Latest Project Completed – CNC Plasma-Cut Porch Railing

We’ve just wrapped up another successful project: a custom CNC plasma-cut railing installed on a porch — crafted with precision and finished to perfection.

This project showcases the detail, strength, and design flexibility that our CNC plasma cutting services offer. Proud to deliver results that combine functionality with standout aesthetics.

Precision

Versatility

Speed

Cost-effectiveness

– Precision Meets Efficiency

Plasma cutting delivers exceptional precision, making it ideal for intricate designs and complex shapes, even on materials with varying thicknesses or irregular forms. This high level of accuracy not only ensures cleaner cuts but also significantly reduces material wastage and minimizes the need for secondary finishing—saving both time and cost.

Versatile CNC Plasma Cutting for Multiple Materials and Industries

Plasma cutting is a highly versatile process that can be used on a wide range of materials—including steel, aluminum, copper, and stainless steel.

This adaptability makes plasma cutting an essential tool across various industries, including manufacturing, construction, automotive, and metal art, where precision and efficiency are critical.

High-Speed Cutting for Maximum Productivity

Plasma cutting is significantly faster than traditional methods like sawing or oxy-fuel cutting. It rapidly pierces through materials and maintains consistent cutting speeds, even on thicker metals. This speed and efficiency lead to shorter production cycles, higher output, and improved overall productivity—making it ideal for high-demand operations.

Compared to other cutting methods, plasma cutting offers excellent cost-efficiency, particularly when working with medium to thick metal sheets. It requires minimal setup time, uses low-cost consumables, and eliminates the need for multiple tools thanks to its ability to handle a wide variety of materials. Combined with its high speed and precision, plasma cutting delivers significant savings in both time and production costs.

CNC Plasma Cutting process to final installed product.Our CNC Plasma Cutting process takes your concept from raw material to fully installed solution with precision, efficiency, and attention to detail at every stage:

1. Design and cut out the product on CNC Plasma.

2. Assembly of the Security Gate.

3 Powder coating. Product in Oven.

4. Final product installed.